PROMAT Insert APKT100305PDER-M KNH10 medium machining

Insert APKT100305PDER-M KNH10 medium machining

PRODUCT DESCRIPTION

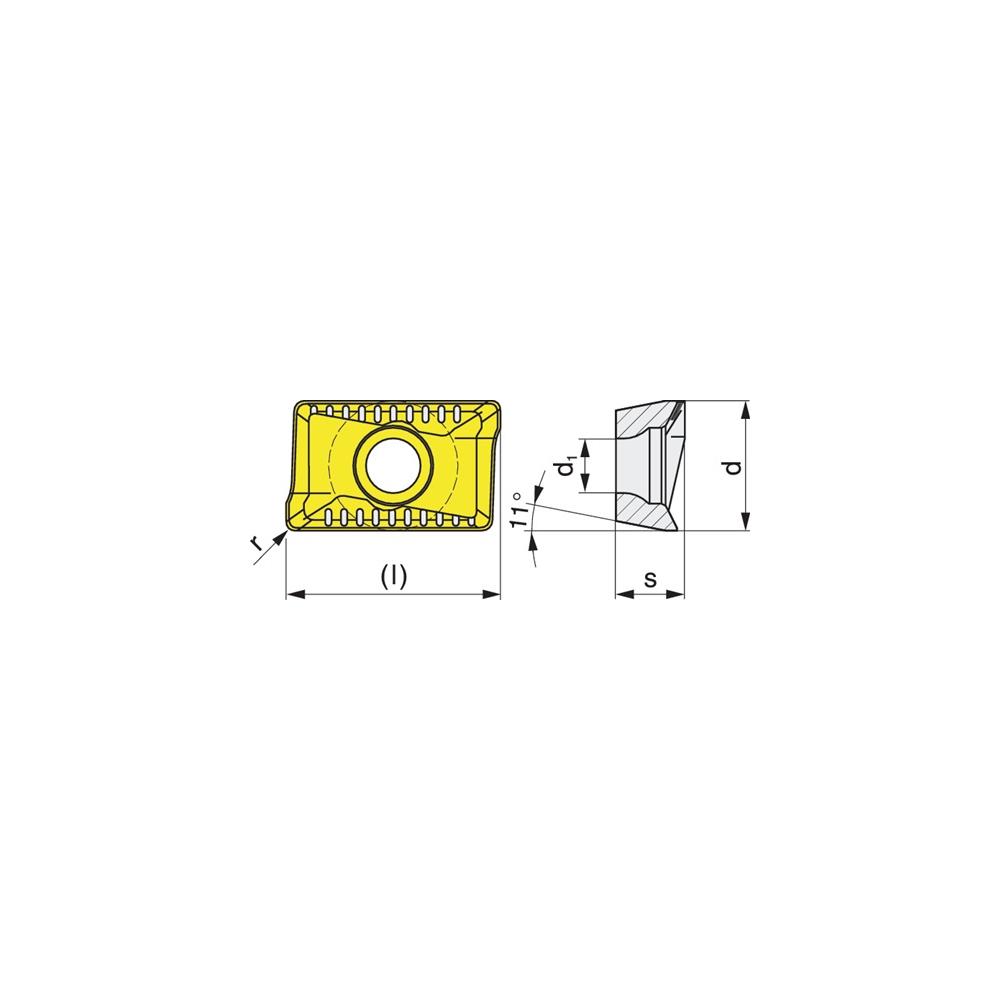

Chip breaker geometry M = for medium processing Further technical information:

– d: 6.7mm

– Area of application: Medium processing

– r: 0.5mm

– d1: 2.88mm

– s: 3,5mm

– l: 11mm

– Max. feed rate: 0.25 mm/rev in steel / 0.19 mm/rev in stainless steel / 0.25 mm/rev in cast / – mm/rev in NI metals / 0.15 mm/rev in superalloys / – mm/rev in hardened steels

– Vc max.: 310 m/min in steel / 185 m/min in stainless / 290 m/min in cast / – m/min in NI metals / 90 m/min in superalloys / – m/min in hardened steels

– Vc min.: 235 m/min in steel / 140 m/min in stainless / 220 m/min in cast / – m/min in NI metals / 45 m/min in superalloys / – m/min in hardened steels

– Min. cutting depth: 1 mm in steel / 1 mm in stainless / 1 mm in cast / – mm in NI metals / 1 mm in superalloys / – mm in hardened steels

– Max. cutting depth: 9 mm in steel / 6.8 mm in stainless / 9 mm in cast / – mm in NI metals / 5.4 mm in superalloys / – mm in hardened steels

– Min. feed rate: 0.1 mm/rev in steel / 0.1 mm/rev in stainless steel / 0.1 mm/rev in cast / – mm/rev in NI metals / 0.1 mm/rev in superalloys / – mm/rev in hardened steels